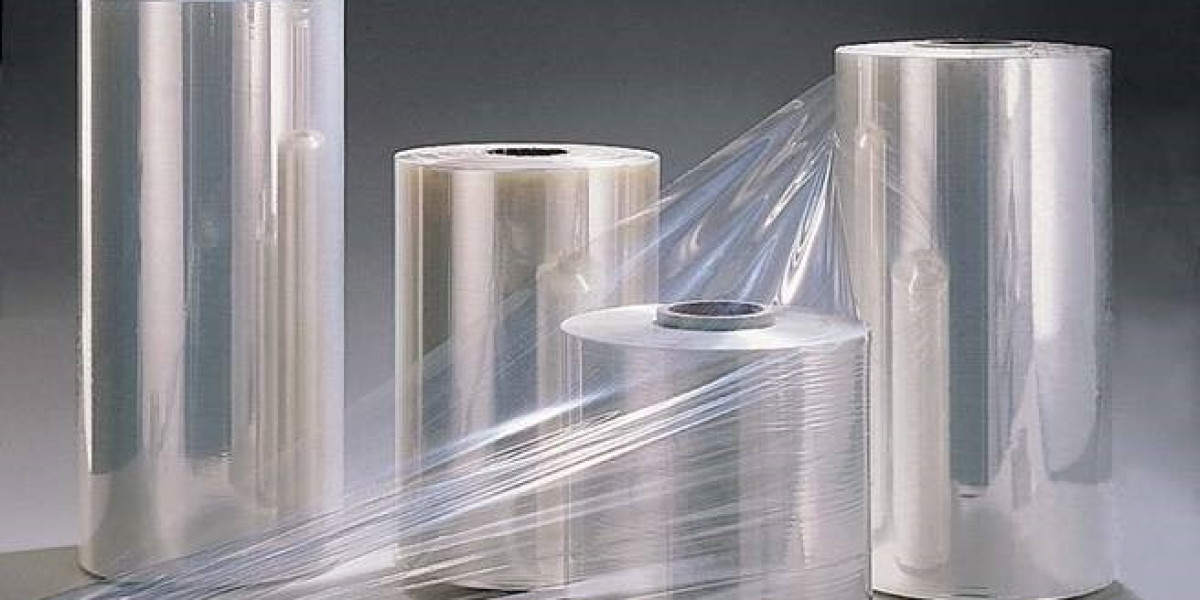

POF Shrink Film plays a subtle but essential role in the performance, appearance, and integrity of finished packaging. Often underestimated, it can quietly determine how your product holds up during transit or how it looks on the shelf. Selecting the wrong film for your equipment or product type can ripple through the supply chain in ways you may not expect.

Many manufacturers first notice the issue through visual signs: wrinkled seals, foggy wraps, or even melted spots. But beyond appearances, the wrong POF shrink film may stretch too much, break under heat, or cause machines to jam. These issues waste time and materials, raise production costs, and frustrate fulfillment timelines.

This is where Jtpackage offers value. We work with packaging teams who understand that film choice isn't just a spec sheet decision—it's a strategic one. The structure and density of each roll need to match your sealing speed, temperature range, and product shape. A mismatch can cause more than downtime; it may hurt your reputation if damaged goods reach customers.

Jtpackage helps clients evaluate shrink film not just by size or gauge, but by how it behaves under real-world packing conditions. With a range of tested films that offer consistent shrink rates and optical clarity, Jtpackage supports your production line while reducing operational risk.

Common packaging lines—like L-bar sealers, side sealers, and flow wrappers—each interact differently with film materials. When businesses use generic or misfitting films, issues like tunnel burn, cloudy film, or weak seams become regular problems. Instead of fighting those issues every shift, companies working with Jtpackage receive matched film solutions that align with machine types, product weights, and packaging designs.

Even shipping and storage play a role. Some films stretch too early under temperature fluctuations, while others stay rigid and fail to conform. That's why Jtpackage advises not only on materials but also on conditions throughout the distribution path.

Whether you package electronics, cosmetics, or food items, choosing the right shrink film is part of presenting a brand image. The film is often the last material your customer sees—don't let a poor seal send the wrong message.

To explore tested, machine-ready POF shrink film options with responsive support, visit https://www.jtpackage.com/news/industry-news/what-is-polyolefin-shrink-film.html